Welding Procedure Data sheets

What Welding Processes are Tested?

Introduction:

Welding is critical in construction, manufacturing, and infrastructure projects across Canada. Ensuring the quality and integrity of welded joints is paramount, necessitating adherence to rigorous standards. In this blog post, we’ll explore the importance of Welding Procedure Testing in Canada, shedding light on the procedures and standards that govern this crucial aspect of welding.

The Significance of Welding Procedure Testing:

Welding Procedure Testing (WPT) is a systematic process designed to evaluate and qualify welding procedures before they are employed in actual fabrication. This meticulous testing is imperative to guarantee that welded joints meet specified quality and safety standards. In Canada, adherence to stringent WPT protocols is essential to uphold the integrity of structures and components.

Key Elements of Welding Procedure Testing in Canada:

1. **Canadian Welding Bureau (CWB) Certification:**

– The CWB is a critical authority in welding certification in Canada.

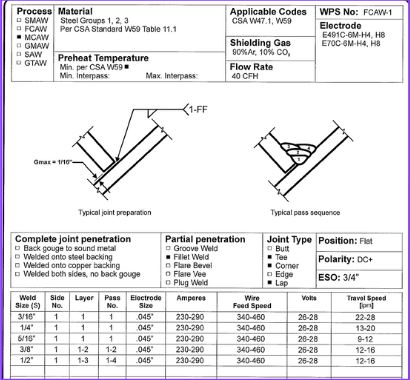

– Welding procedure Datasheet (WPDS) processes align with CWB standards, ensuring consistency and reliability in welding procedures.

2. **Procedure Qualification Record (PQR):**

– A document that records the essential variables and results of welding procedure tests.

– Serves as a crucial reference for ensuring repeatability and reliability in future welds.

3. **Welding Procedure Specification (WPS):**

– Derived from the PQR, the WPS provides detailed instructions for a specific welding procedure.

– Acts as a guideline for welders to follow during actual fabrication.

4. **Essential Variables:**

– Variables such as material type, thickness, welding position, and filler metal type are considered during testing.

– Each variable is systematically tested to determine its impact on the quality of the weld.

5. **Performance Qualification (PQ):**

– Involves testing the skills and capabilities of welders to ensure they can execute the specified welding procedure correctly.

Benefits of Rigorous WPT in Canada:

1. **Quality Assurance:**

– Rigorous testing ensures that welding procedures meet or exceed industry standards, guaranteeing the quality of welded joints.

2. **Safety Compliance:**

– Adherence to WPT protocols contributes to the safety and reliability of structures, which is crucial in sectors like construction and energy.

3. **Industry Consistency:**

– Standardized WPT processes foster consistency across the welding industry, promoting reliability and interoperability.

Conclusion:

Welding Procedure Testing in Canada is a comprehensive and structured approach to guarantee welded joints’ quality, safety, and reliability. As the welding industry continues to evolve, a commitment to rigorous testing ensures that structures and components stand the test of time. By embracing and upholding these testing standards, Canada reinforces its dedication to precision and excellence in welding, contributing to the integrity of its diverse projects and industries.

Welder Qualification

Upon successful completion of their weld test, the welder will receive a qualification letter, which is valid for 2 yrs. The company is CWB certified, the welder is a qualified welder to CSA W47.1. The company certification covers the entire quality control program which includes accepted data sheets and procedure specifications, the use of certified electrodes and qualified personnel. Having a CWB welder qualification is one part in the CWB quality control program and does not make a welder “certified” to perform structural welding outside of a company certification program.

AXIS Test Availability

We have testing available almost every week, Thursdays in July & August and Fridays; September thru June. Pricing depends on testing being completed.