How to become a certified welding company

You may be considering becoming CWB Certified (or CSA W47.1 or 2 Certified) and would like to know what steps to take to become a certified welding company.

This post is intended to help you navigate the possibly confusing world of the Canadian Welding Bureau Group a little bit better.

(Disclaimer: things may change, but hopefully this is a helpful tool)

STEP 1 – Determine what “Division” your company will be or is

Division 3 – This is a company that only sub contracts from division 2 & 1 companies. These companies

have qualified procedures and welders, but are not required to have an engineer on staff or retainer.

Division 2 – This is a company that will retain a Welding Engineer and is able to bid on structural steel

projects.

Division 1 – This is a company that has a Welding engineer on as a permanent employee. Companies that

build bridges for example, must be Division 1.

STEP 2 – Get a Quote from CWB (Canadian Welding Bureau).

STEP 3 – Determine who will be the Welding Supervisor.

This is the step that can often hold up certification.

The welding supervisor will be responsible for and must understand the companies welding practices and

procedures.

i. Options: Hire someone who is A CWB Welding Supervisor.

ii. Take or send someone on the 1 week CWB Supervisor course

iii. Take or have someone do the on-line welding supervisor course.

Your company will not be certified until you have a qualified supervisor in place.

STEP 4) If you are becoming a Div 2 Shop, you will now have to choose a Retained engineer.

There are a few around Winnipeg, each with a different specialty.

STEP 5 – Determine what Processes you require certification for

a. SMAW

b. GMAW

c. FCAW

d. MCAW

e. Other

Most Welding Engineering companies will provide you with an option to purchase a prequalified welding procedure and data sheet package to streamline your registration process.

If you require additional procedure testing, wait until after you are certified to complete the testing. Becoming certified based on procedure testing may delay your certification process.

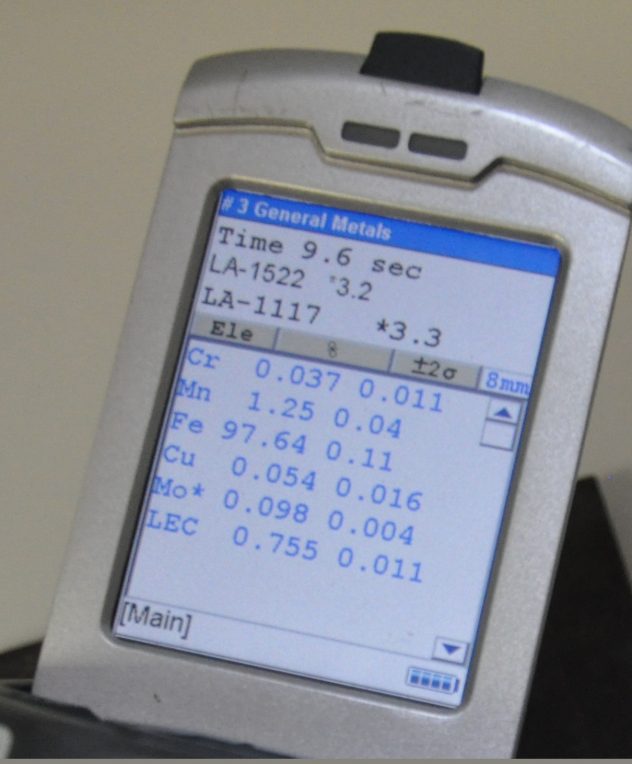

STEP 6 – Welder Qualification:

As part of your quality control for CWB certification you will be required to have qualified welders. You can test your welders at your facility or at a facility like AXIS

Inspection Group Ltd. I recommend that you use your CWB audit dates as welder testing times to be most cost efficient. Any additional testing or retesting can be done at AXIS which is also cost efficient.

Reasons to send your welders to test at a CWB Welder Test Centre such as AXIS:

1.Testing at a test centre is cost efficient as it reduces down time of machines, and keeps equipment available for production.

2. The other employees aren’t distracted during the testing, watching a buddy test.

3. All prep and mechanical testing is done at AXIS, your welder just comes in, tests and leaves.

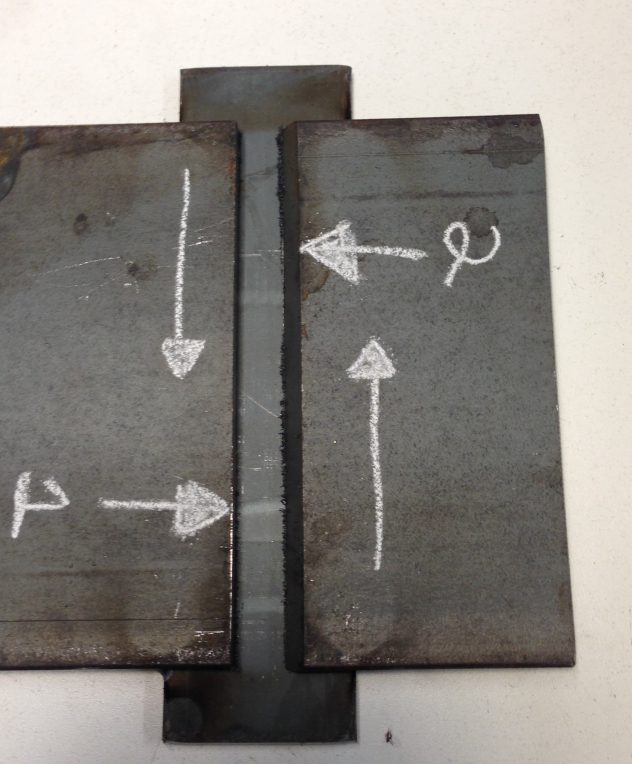

To order high quality test plates for testing at your facility please go here.