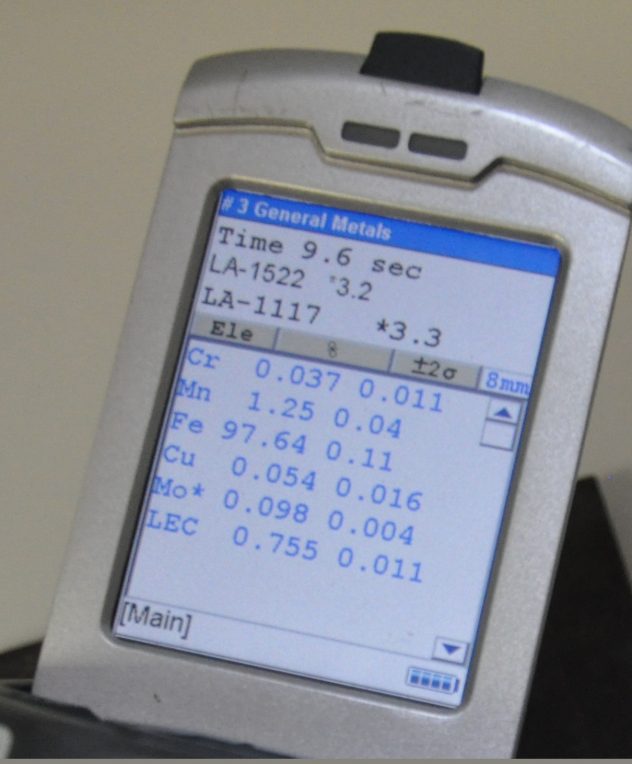

Equipment Inspection

AXIS Inspection offers an exciting service in the inspection and testing of equipment. Many of the items we inspect are governed by Codes, standards, specifications, and safety regulations, but another whole group of items is simply done because the client sees value in having their equipment inspected.

Why inspect something if you don’t have to?

We often get the question, “Do I have to have this inspected?” The answer is usually no, as that item has no specific requirements. However, we are seeing a trend towards preventative maintenance and safety inspections.

Safety Inspections:

Many pieces of equipment are inspected because there have been injuries associated with equipment failure, or an assessment has been done, and it has been determined that the likelihood of equipment failure and the possibility of injury are significant enough to warrant a third-party inspection.

Preventative Maintenance:

Inspecting equipment before a breakdown is a proactive and cost-efficient way to ensure productivity remains constant. We can inspect equipment during scheduled downtime and ensure any minor deficiencies are identified and repaired, rather than the equipment breaking down during production. This approach empowers you to stay in control of your equipment’s performance.

Preventative maintenance and inspection of industrial equipment are the equivalent of an oil change in your car. Just as you check and change the oil regularly to prevent engine failure, inspecting your equipment during a down day ensures that when the big orders come in, your production isn’t delayed due to equipment breakdown. This analogy brings the concept of equipment inspection to a relatable and familiar context.