common terms in Inspection and Testing

As an inspection and testing company, we are often asked what our industry’s abbreviations mean. Terms related to testing that we use around here every day may be confusing for others, and we realized that a cheat sheet was in order:

NDE or NDT

– Refers to Non-Destructive Examination or Testing.

Types of NDE or NDT include the following:

VT

– Visual Testing or Inspection is precisely what it sounds like. It’s to look at something without the use of any additional equipment.

UT

– Ultrasonic Flaw Detection, or Shear Wave Testing, is similar to when you see your baby’s first ultrasound in the womb. Just as the technician is looking for “defects” in the growing fetus, our technicians are looking for defects in the material or weld.

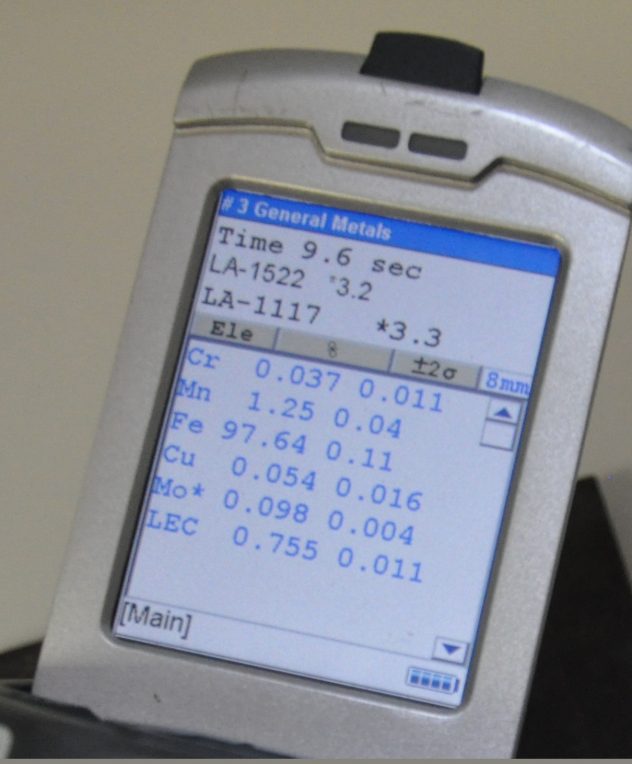

XRF or PMI

– X-Ray Fluorescence or Positive Material Identification is equipment that tests for the chemical composition of a material. Metal or earth substances are all made up of chemical compositions.

The analysis will tell you what percentage of each chemical is found in the material.

RT

– Refers to Gamma-Ray and X-Ray Testing, which is just like looking at a broken bone at the doctor’s office. X-ray testing will look for “defects” in a weld. What’s neat, though, is that this machine can be much stronger than what you get at the sport clinic. Our X-ray (gamma rays) can penetrate 3 inches of steel!

PT or LPI

– Liquid Penetrant Testing, or Dye Penetrant Testing, is a test that uses red dye working in 2 stages. First, the material is prepared, and then the dye is applied. If any surface cracks are present, the red dye will adhere to that area.

MT or MPI

– Magnetic Particle Testing, or Inspection, uses equipment that uses an electromagnet to induce a magnetic field into the part we are testing. Discontinuity in the material allows the magnetic field ( Flux) to leak. Ferrous iron particles are then applied to the part. If an area of flux leakage is present, the particles will be attracted to this area. The particles will build up at the leakage area and form what is known as a discontinuity.

We hope some of these terms are now a bit more clear. Feel free to contact us if you have any questions.